In the world of construction, there are many materials and components that play crucial roles in building strong, safe, and durable structures. One such component is the GI angle. But what exactly is a GI angle? Why are they so important in construction? This blog will explain everything you need to know about GI angles in simple terms.

What Are GI Angles?

Definition of GI Angles

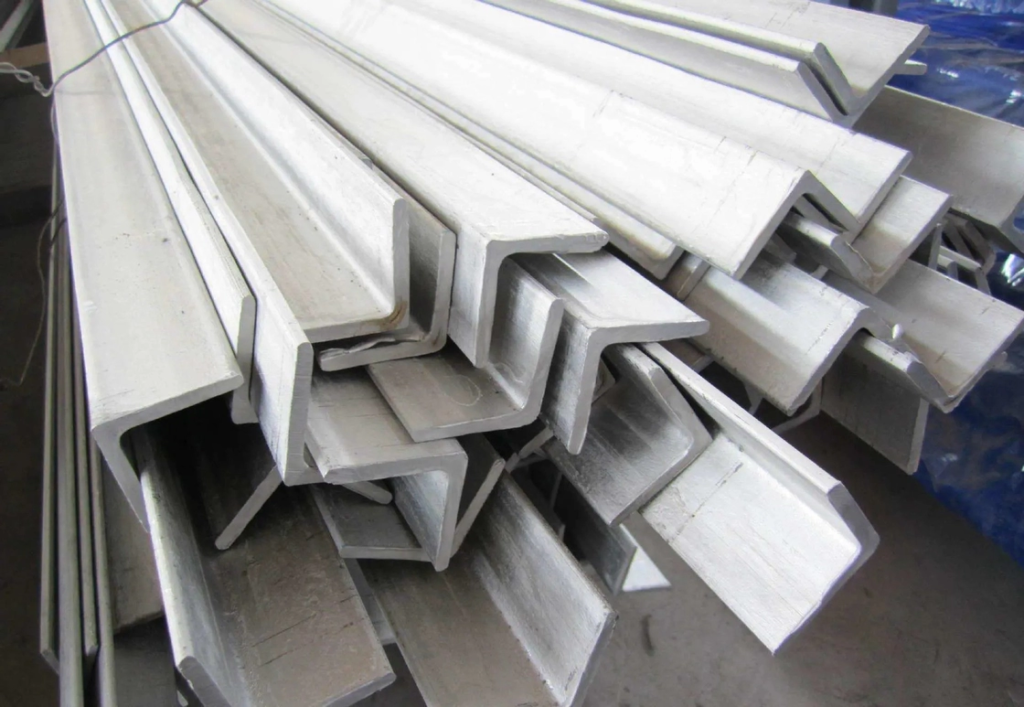

GI angles, short for Galvanized Iron angles, are structural steel pieces shaped like the letter “L”. They are made from iron or steel and coated with a layer of zinc to protect them from rust and corrosion. This zinc coating process is known as galvanization.

Common Sizes and Shapes

GI angles come in various sizes and thicknesses, depending on their intended use. They can have equal or unequal sides, meaning the lengths of the two sides of the “L” can either be the same or different. This versatility makes them suitable for a wide range of applications.

The Manufacturing Process

How GI Angles Are Made

The production of GI angles involves several steps:

- Raw Material Preparation: The process begins with selecting high-quality steel or iron.

- Shaping: The raw material is shaped into an “L” form through a process called rolling.

- Galvanization: The “L” shaped steel is then dipped into a bath of molten zinc. This process coats the steel with a protective layer of zinc.

- Cooling and Inspection: After galvanization, the angles are cooled and inspected to ensure they meet quality standards.

Note:- Are you working on a construction project in Dubai and need high-quality GI angles? Look no further! Explore our wide range of GI Angles in Dubai, perfect for ensuring the strength and durability of your structures. Whether you’re building a new home, an office, or any other structure, our GI angles are the ideal choice for superior support and longevity.

Importance of Galvanization

Galvanization is crucial because it protects the steel from rust and corrosion. This means that GI angles can be used in outdoor and humid environments without deteriorating quickly.

Applications of GI Angles in Construction

Structural Support

One of the primary uses of GI angles in construction is to provide structural support. They are often used in the framework of buildings, bridges, and towers. Their “L” shape makes them ideal for reinforcing corners and edges, which are often the most vulnerable parts of a structure.

Roofing and Cladding

GI angles are also commonly used in roofing and cladding. They help secure roofing sheets and panels in place, ensuring they remain stable and can withstand various weather conditions.

Furniture and Fixtures

In addition to large-scale construction projects, GI angles are also used in the manufacturing of furniture and fixtures. For example, they can be found in the frames of tables, chairs, and shelving units.

Electrical and Plumbing Systems

GI angles play a role in supporting electrical and plumbing systems. They can be used to create brackets and supports for pipes and conduits, keeping these systems secure and organized.

Advantages of Using GI Angles

Durability

One of the main advantages of using GI angles is their durability. The galvanized coating protects the steel from rust and corrosion, extending the lifespan of the angles and the structures they support.

Strength

GI angles are incredibly strong and can bear heavy loads. This makes them ideal for use in construction projects where structural integrity is paramount.

Versatility

As mentioned earlier, GI angles come in various sizes and shapes, making them suitable for a wide range of applications. Whether you need them for a small furniture project or a large building, there’s a GI angle to fit your needs.

Cost-Effective

Despite their many benefits, GI angles are relatively affordable. Their long lifespan and low maintenance requirements make them a cost-effective choice for many construction projects.

How to Choose the Right GI Angle

Assess Your Needs

Before selecting a GI angle, it’s important to assess your specific needs. Consider the size, load-bearing capacity, and environment in which the angles will be used.

Check Quality Standards

Ensure that the GI angles you choose meet industry quality standards. Look for certifications and quality marks that indicate the angles have been tested and meet required specifications.

Consider the Environment

Think about the environment where the GI angles will be used. For example, if they will be exposed to harsh weather conditions or chemicals, you may need angles with additional protective coatings.

Installation Tips for GI Angles

Proper Handling and Storage

Before installation, make sure to handle and store GI angles properly to prevent damage. Store them in a dry place and avoid stacking them in a way that could cause deformation.

Use the Right Tools

When installing GI angles, use the appropriate tools for cutting, drilling, and fastening. This will ensure a secure fit and reduce the risk of damage.

Follow Safety Guidelines

Always follow safety guidelines when working with GI angles. Wear appropriate protective gear, such as gloves and safety glasses, and be aware of your surroundings to prevent accidents.

Secure Connections

Ensure that all connections are secure and properly aligned. Loose or misaligned connections can compromise the structural integrity of the project.

Maintenance of GI Angles

Regular Inspections

Conduct regular inspections of GI angles to check for signs of wear and tear, such as rust or deformation. Early detection of issues can prevent more serious problems down the line.

Cleaning

Keep GI angles clean by removing dirt, debris, and other contaminants that can cause corrosion. Use mild cleaning agents and avoid harsh chemicals that can damage the zinc coating.

Repairs and Replacements

If you notice any damage or significant wear, repair or replace the affected GI angles promptly. Ignoring damaged components can compromise the safety and stability of the entire structure.

Environmental Impact of GI Angles

Sustainable Construction

Using GI angles can contribute to sustainable construction practices. Their long lifespan and durability mean that structures built with GI angles require fewer repairs and replacements, reducing waste.

Recycling

GI angles are recyclable, which further enhances their environmental benefits. At the end of their life cycle, they can be melted down and reused, minimizing their impact on the environment.

Conclusion

GI angles are an essential component in many construction projects. Their strength, durability, and versatility make them invaluable in building safe and reliable structures. By understanding their benefits and applications, you can make informed decisions when choosing materials for your construction projects.

For more insightful articles related to this topic, feel free to visit globaltoptrend.com